Introduction to Welding Wire Mesh Machinery

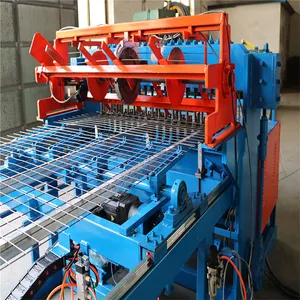

Welding wire mesh machinery represents a category of industrial equipment designed for the production of wire mesh, a versatile material used across various sectors. This machinery facilitates the creation of mesh by welding wires at intersections, resulting in a stable and uniform grid pattern. The machines vary in specifications to accommodate different wire diameters, mesh widths, and hole sizes, ensuring a broad range of mesh styles for diverse applications.

Types and Applications

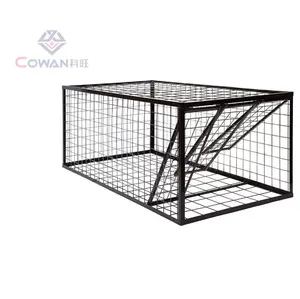

The welding wire mesh machine category encompasses several types, each tailored for specific manufacturing needs. Fence mesh welding machines are instrumental in creating barriers for properties, while roll mesh welding machines are pivotal in constructing reinforcing materials for the building industry. For the agricultural sector, machines like the chicken cage mesh welding machine are specialized for producing enclosures for poultry. These machines serve critical functions in mining, construction, agriculture, and transportation, highlighting their importance in industrial operations.

Features and Materials

A wire mesh welding machine is engineered to handle various materials, including stainless steel, galvanized, and low-carbon wires, offering adaptability to different project requirements. The machines are designed for efficiency, with features that promote automation and ease of operation, minimizing the need for constant oversight. This ensures a seamless production process, from raw wire input to finished mesh output.

Advantages of Modern Machinery

Modern wire mesh machines boast enhanced productivity and durability, essential for meeting the demands of large-scale industrial manufacturing. The automation integrated into these machines ensures consistent quality, with end products that are structurally sound, aesthetically pleasing, and free from defects. The operational efficiency of these machines also contributes to a reduction in production time and material waste, making the manufacturing process more sustainable.

Considerations for Selection

Selecting the right welding wire mesh equipment involves considering the intended application, desired mesh specifications, and production volume. It's crucial to choose a machine that aligns with the operational scope, ensuring that the mesh produced meets the application's structural and aesthetic requirements. Prospective buyers should assess the machine's compatibility with their production needs to ensure an efficient and effective manufacturing process.

Applications in Electronics and Beyond

Beyond traditional uses, wire meshes produced by welding wire mesh machinery are integral to various electronic devices. They are found in air conditioning systems, metering devices, and as noise filters, showcasing the material's versatility. The precision and quality of mesh required for these applications underscore the necessity for reliable and capable machinery in production lines.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4