Popular in your industry

Related Searches:

Top categories

About used sheet metal bending machine

Introduction to Used Sheet Metal Bending Machine

A used sheet metal bending machine is a crucial piece of equipment in the metal fabrication industry. It is designed to bend sheet metal into various shapes and sizes, allowing for the creation of a wide range of products such as automobile parts, household appliances, and industrial components. These machines are cost-effective alternatives for businesses looking to expand their metalworking capabilities without investing in brand new equipment.

Technical Specifications of a Used Sheet Metal Bending Machine

When considering purchasing a used sheet metal bending machine, several technical specifications need to be taken into account. These include the bending length, bending capacity, motor power, back gauge range, and the machine's overall dimensions. For example, a typical used sheet metal bending machine may have a bending length of 2 meters, a bending capacity of 3 mm, a motor power of 5 kW, a back gauge range of 600 mm, and dimensions of 2500 x 1200 x 1600 mm.

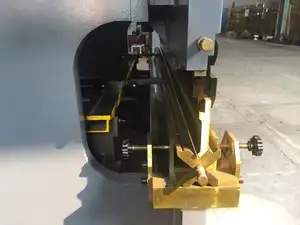

Types of Used Sheet Metal Bending Machines

There are several types of used sheet metal bending machines available in the market, each designed for specific bending applications. These include press brakes, folding machines, and roll benders. Press brakes are widely used for precision bending, folding machines are ideal for complex bends, and roll benders are suitable for cylindrical bending. Understanding the different types can help buyers choose the most suitable machine for their specific needs.

Advantages of Purchasing a Used Sheet Metal Bending Machine

Investing in a used sheet metal bending machine offers several advantages for businesses. Firstly, it allows for cost savings compared to buying new equipment. Secondly, used machines are readily available for immediate use, reducing lead times. Additionally, purchasing used equipment from reputable sellers can provide quality assurance and reliable performance. Moreover, used machines often come with additional tooling and accessories, further enhancing their value.

Factors to Consider When Buying a Used Sheet Metal Bending Machine

When looking to buy a used sheet metal bending machine, several factors need to be considered to ensure the right investment. These include the machine's condition, age, brand reputation, maintenance history, and the availability of spare parts. Inspecting the machine in person or through detailed documentation can help buyers assess its overall quality and performance. Furthermore, understanding the seller's reputation and after-sales support is crucial for a smooth purchasing experience.

Applications and Use Scenarios of Used Sheet Metal Bending Machines

Used sheet metal bending machines find applications in a wide range of industries, including automotive, aerospace, construction, and manufacturing. These machines are used to create components such as brackets, enclosures, panels, and frames with precise bends and angles. Whether in small workshops or large-scale production facilities, sheet metal bending machines play a critical role in shaping metal materials for various purposes.

Key Features of a Quality Used Sheet Metal Bending Machine

Quality used sheet metal bending machines exhibit certain key features that differentiate them from inferior models. These features include robust construction using high-quality materials, advanced bending technology for precise results, user-friendly controls for efficient operation, and safety mechanisms to protect operators. Additionally, modern used machines may offer automation capabilities, digital displays, and programmable settings for enhanced productivity.

Maintenance Tips for Used Sheet Metal Bending Machines

Proper maintenance is essential to ensure the longevity and performance of a used sheet metal bending machine. Regular cleaning of the machine surfaces, lubrication of moving parts, and inspection of hydraulic systems can prevent premature wear and damage. Additionally, monitoring the machine for unusual noises, vibrations, or deviations from normal operation can help identify potential issues early on. Following the manufacturer's maintenance guidelines and scheduling routine servicing can keep the machine in optimal working condition.

Second-hand Sheet Metal Bending Machines for Sale on Alibaba.com

For businesses looking to purchase used sheet metal bending machines, Alibaba.com offers a wide selection of reliable sellers providing quality equipment. Whether seeking a specific type of bending machine or looking for customized solutions, buyers can explore various listings on the platform. With detailed product descriptions, images, and seller ratings, Alibaba.com provides a transparent and secure marketplace for sourcing used sheet metal bending machines.