Popular in your industry

Related Searches:

Top categories

About steel roll mill

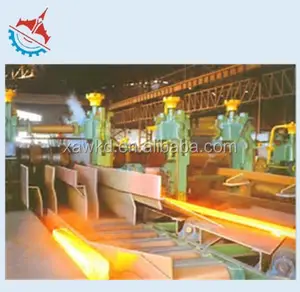

Introduction to Steel Roll Mill

A steel roll mill is a crucial piece of machinery used in the metalworking industry for shaping and forming metal products. It plays a significant role in the manufacturing process of various metal components, providing precision and efficiency in producing high-quality steel products. Steel roll mills are commonly used in applications such as hot steel rolling, plate milling, and hot strip milling.

Technical Specifications of Steel Roll Mills

Steel roll mills are designed to handle a wide range of metal thicknesses and materials. They typically have robust construction with high-strength materials to withstand the rigors of heavy-duty operations. The power capability of a steel roll mill can vary, with some models offering above 35-40 hp for enhanced performance. These mills can have a maximum range of 3-4 tons and are available in various sizes, with common lengths ranging between 60 and 130 feet.

Hot Steel Rolling Process

The hot steel rolling process involves passing the metal through a pair of rolls to reduce its thickness and change its cross-sectional area. This process is vital for producing steel sheets, bars, and other structural components with precise dimensions and surface finish. A steel roll mill utilized in hot steel rolling must have the capability to withstand high temperatures and pressures while maintaining accuracy and consistency in the final product.

Steel Roll Mill in Plate Milling

Plate milling is a specialized application where steel roll mills are used to produce flat metal sheets of uniform thickness. These mills need to have adjustable roll gaps and precise control systems to ensure the desired plate thickness is achieved consistently. Plate mills are essential in industries such as shipbuilding, construction, and automotive manufacturing for creating large steel plates used in various structural components.

Advantages of Hot Strip Mills

Hot strip mills are a type of steel roll mill designed specifically for rolling steel strips at high temperatures to achieve the desired thickness and surface quality. They offer advantages such as high productivity, reduced energy consumption, and improved material properties. Hot strip mills are crucial in the production of hot-rolled steel coils used in a wide range of industrial applications.

Choosing the Right Steel Roll Mill

When selecting a steel roll mill for your business, it is essential to consider factors such as the required production capacity, material specifications, and desired output quality. Different models of steel roll mills offer varying features and capabilities, so understanding your specific production needs is crucial in making the right choice. Additionally, factors like maintenance requirements, technical support, and supplier reputation should also be taken into account when choosing a steel roll mill.

Efficient Use of Steel Roll Mills

To ensure the efficient operation of a steel roll mill, proper maintenance and regular servicing are essential. Routine checks on the mill's components, lubrication systems, and alignment are necessary to prevent downtime and maintain optimal performance. Operators should be trained in the correct operation of the mill to maximize productivity and prolong the machine's lifespan.

Enhancing Productivity with Hot Rolling Mills

In industries where high-volume production of steel products is required, hot rolling mills play a crucial role in enhancing productivity and efficiency. These mills are capable of processing a wide range of steel materials quickly and accurately, making them ideal for mass production scenarios. By investing in a high-quality hot rolling mill, businesses can streamline their manufacturing processes and meet market demands effectively.

Maintaining Steel Roll Mills for Longevity

Proper maintenance of steel roll mills is essential to ensure their longevity and consistent performance. Regular inspections, cleaning, and calibration of the mill's components are necessary to prevent wear and tear. Additionally, timely replacement of worn parts and adherence to maintenance schedules recommended by the manufacturer can extend the lifespan of the mill and reduce the risk of unexpected breakdowns.

Optimizing Steel Production with Plate Mills

Plate mills are vital equipment in the steel industry for producing flat metal sheets used in a variety of applications. By optimizing the operation of plate mills through accurate setup, monitoring of process parameters, and quality control measures, manufacturers can enhance the quality and efficiency of their steel production. Plate mills offer versatility in producing custom-sized plates, making them essential machinery for businesses seeking precision and reliability in their steel manufacturing processes.