Introduction to Steel Flat Bar Production Lines

The industrial landscape is continuously evolving, and at the heart of metal fabrication is the steel flat bar production line. This machinery is a cornerstone in the manufacturing sector, providing a streamlined process for producing flat steel bars, a fundamental component in various construction and manufacturing applications. The production line is designed to cater to a range of requirements, ensuring adaptability across different industrial environments.

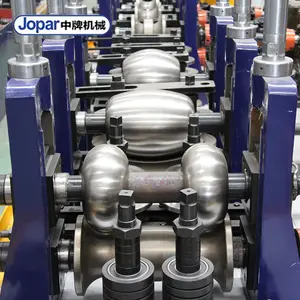

Components and Functionality

A typical steel flat bar production line comprises several integral components such as rolling mills, metal processing lines, and sometimes, ancillary equipment like tile making machinery. The core of the line, the rolling mill, is responsible for the thermal and mechanical processing of metal to produce flat bars with precise dimensions. The choice of motor, gear, and gearbox is critical in defining the efficiency and performance of the line. These components work in unison to ensure seamless operation and consistent output.

Types and Applications

The versatility of the steel flat bar production line is evident in its various types, each tailored to specific industry needs. From compact lines designed for small-scale production to extensive setups for heavy industrial use, the range is comprehensive. These lines are employed in manufacturing plants, building material shops, and machinery repair shops, highlighting their widespread applicability in producing flat steel bars used in construction, automotive, and machinery manufacturing.

Features and Materials

In the realm of steel flat bar production, the emphasis on features such as operational stability, precision control, and energy efficiency cannot be overstated. The materials used in the construction of these lines are selected for their durability and performance under strenuous conditions. This ensures that the production line can withstand the rigors of continuous operation while maintaining the integrity of the flat bars produced.

Advantages of Modern Production Lines

Modern steel flat bar production lines are engineered to be more than just functional; they are innovatively designed to enhance productivity and reduce waste. The integration of advanced technology allows for better control systems, resulting in improved precision and reduced downtime. The adaptability of these lines to various geographical locations, such as Vietnam, Indonesia, and Uzbekistan, underscores their global relevance and the ability to meet diverse operational standards.

Choosing the Right Production Line

Selecting the appropriate steel flat bar production line is a decision that requires careful consideration of the specific needs of a manufacturing facility. Factors such as production capacity, space constraints, and the nature of the end product play a pivotal role in this selection process. While the market offers both new and used options, the choice ultimately hinges on the balance between cost-effectiveness and the assurance of reliability and productivity.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4