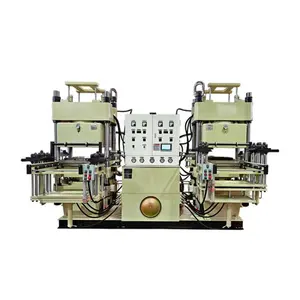

Silicone Compression Molding Machine Overview

Silicone compression molding machines are pivotal in the manufacturing sector, designed for the efficient production of a wide array of silicone products. This category encompasses machinery that applies heat and pressure to silicone material to shape it into durable, high-precision components. These machines are integral to industries requiring the mass production of consistent and reliable silicone parts.

Types and Applications

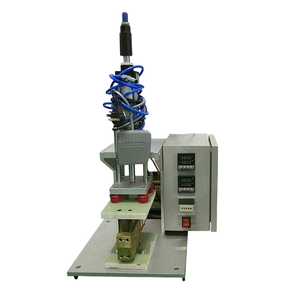

There are various types of silicone molding equipment, each suited to specific applications. From simple manual presses to advanced automatic systems, the range includes options for startups to large-scale operations. The versatility of these machines allows for their use in creating medical devices, automotive parts, seals, gaskets, and kitchenware, demonstrating their extensive applicability across sectors.

Features and Materials

A silicone compression molding machine is typically characterized by its robust construction and precision engineering. Constructed from high-grade metals, these machines are designed for longevity and consistent performance. Features may include programmable logic controllers (PLCs), precision temperature control, and hydraulic pressure systems, which together ensure the meticulous formation of silicone products.

Advantages of Silicone Molding Machines

The advantages of utilizing a silicone rubber molding machine are manifold. They offer efficient production cycles and energy consumption, reducing operational costs while maximizing output. The precision of these machines minimizes material waste, enhancing the sustainability of production processes. Additionally, their ability to produce complex shapes with high accuracy makes them indispensable in specialized manufacturing scenarios.

Operational Efficiency

Operational efficiency is a hallmark of the silicone press machine. With advancements in technology, these machines provide streamlined operations and are capable of handling high-volume production with minimal downtime. The integration of modern control systems allows for easy monitoring and adjustment of the molding process, ensuring optimal productivity.

Choosing the Right Machine

Selecting the appropriate silicone compression press is crucial for meeting specific production needs. Factors to consider include the machine's capacity, the complexity of the products to be manufactured, and the desired level of automation. Alibaba.com serves as a platform where businesses can connect with a diverse range of suppliers to find the machine that best fits their operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4