Understanding Rebar Molding Machines

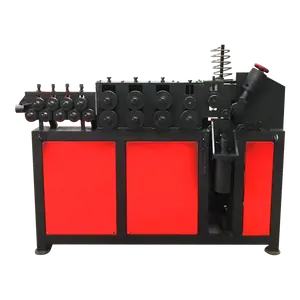

Rebar molding machines, essential in the construction and metalworking industries, offer a practical solution for shaping metal rods into desired configurations. These machines are pivotal for projects requiring precision in bending steel bars, which are otherwise challenging to mold by hand.

Types and Applications

The versatility of rebar benders is evident in their various models, from manual to fully automated CNC versions. Manual rebar benders cater to smaller projects, where intricate bending is not required, while CNC rebar benders are suitable for larger-scale operations demanding high precision and efficiency. The application of these machines spans across construction sites, metalworking shops, and facilities dedicated to infrastructure development.

Features and Materials

A rebar bending machine is designed to handle the rigors of metal shaping. Constructed from robust materials, these machines can manipulate steel bars into angles and curves with accuracy. Some models combine cutting and bending functionalities, enhancing their utility while conserving workspace. The operational features often include an electromagnetic system that precisely controls metal feed and speed, ensuring consistent results.

Advantages of Using a Rebar Molding Machine

The strategic use of a steel bar bender in metal fabrication can significantly enhance productivity. It reduces the labor intensity of manually shaping rebar and increases the uniformity of the output. Moreover, the integration of advanced technology in automated models allows for complex designs that would be difficult to achieve manually.

Choosing the Right Machine

Selecting a rebar molding machine from the array of options available on Alibaba.com involves considering the scale of work, the complexity of the rebar shapes required, and the operational capacity of the machine. Prospective buyers can explore a comprehensive catalog of machines, each designed to meet specific bending needs without compromising on the integrity of the metal.

Support and Maintenance

While Alibaba.com facilitates the connection between buyers and suppliers of rebar processing equipment, it is essential to acknowledge the importance of maintenance and operational support. Suppliers on the platform may offer various services to ensure the longevity and proper functioning of the machinery, contributing to the overall value of the investment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4