Popular in your industry

Related Searches:

Top categories

About rack and pinion gear calculation

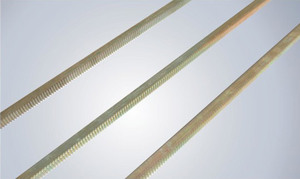

A rack and pinion gear calculation is a fundamental method in the design and engineering of mechanical systems that utilize this specific type of gearing. A rack and pinion gear system consists of a linear gear, known as the rack, and a rotational gear with teeth, known as the pinion. These two components work in tandem to convert rotational motion to linear motion or vice versa. A rack and pinion system is widely used in various applications, including steering mechanisms in automobiles, CNC machines, and linear actuators.

How to calculate the rack gear ratio?

The rack gear ratio is a fundamental parameter that defines the relationship between the rotational motion of the pinion and the linear motion of the rack. It is crucial for determining the speed and torque characteristics of a rack and pinion system. The rack gear calculation involves the number of teeth on the pinion and the pitch of the rack, which is the distance between two consecutive teeth on the rack. The gear ratio is calculated as the ratio of the number of teeth on the pinion to the pitch of the rack. This relationship quantifies how many rotations of the pinion are required to move the rack a certain distance.

For example, if a pinion has 10 teeth and the rack has a pitch of 2 mm (distance between two teeth), the gear ratio would be 10:2 or 5:1. This means that for every rotation of the pinion, the rack moves a linear distance equal to five times the pitch of the rack. The gear ratio significantly impacts the performance of the system. A higher gear ratio will result in faster linear motion of the rack for a given rotational speed of the pinion but may compromise torque, while a lower gear ratio will provide higher torque at the expense of linear speed. The gear ratio is a key parameter that engineers consider during the design phase of a rack and pinion system to ensure that it meets the specific requirements of the application.

What is the rack and pinion gear calculation formula?

The rack and pinion gear calculation formula is a mathematical expression that precisely determines the relationship between the rotational motion of the pinion and the linear motion of the rack. As a fundamental component of the system, this formula provides engineers with the necessary tools to design and analyze rack and pinion setups effectively. The rack pinion calculation formula is commonly expressed as:

Gear Ratio = Number of Teeth on Pinion / Pitch of the Rack

Where:

The number of teeth on the pinion denotes the total count of gear teeth on the rotational gear, and it is represented by the variable 'T.'

The pitch of the rack represents the distance between two consecutive teeth on the linear gear, and it is denoted by the variable 'P.'

By utilizing this formula, engineers can precisely determine the gear ratio of a rack and pinion system, providing a quantitative measure of how rotational and linear motion are interrelated. This enables the calculation of essential parameters such as linear speed, torque, and the number of rotations required to achieve a specific linear displacement. The gear ratio serves as a foundational element in the design and optimization of rack and pinion systems, ensuring their efficiency and effectiveness in various industrial and mechanical applications.

How to determine the gear ratio for rack and pinion?

Determining the gear ratio for a rack and pinion system is a critical step in the design and selection process. The gear ratio quantifies the relationship between the rotational motion of the pinion and the resulting linear motion of the rack. It is essential for understanding the speed and torque characteristics of the system and ensuring that it meets the specific requirements of the application. To determine the gear ratio, the number of teeth on the pinion and the pitch of the rack must be known. The gear ratio formula, as mentioned earlier, is the ratio of the number of teeth on the pinion to the pitch of the rack. This formula provides a straightforward method to calculate the gear ratio for a given rack and pinion setup. Additionally, the gear ratio can be directly determined by examining the manufacturer's specifications or technical drawings for the rack and pinion components. These documents typically provide the necessary information, including the number of teeth on the pinion and the pitch of the rack, allowing for the gear ratio to be easily identified. Understanding the gear ratio is crucial for selecting the appropriate rack and pinion system for a particular application. For applications where speed is a priority, a higher gear ratio is preferred, as it results in faster linear motion for a given rotational speed. Conversely, in scenarios where torque is essential, a lower gear ratio is favored, as it provides higher mechanical advantage at the expense of linear speed. By determining and considering the gear ratio, engineers and designers can optimize the performance of rack and pinion systems to meet the specific demands of their respective applications.