Popular in your industry

Related Searches:

Top categories

About pvd chrome machine

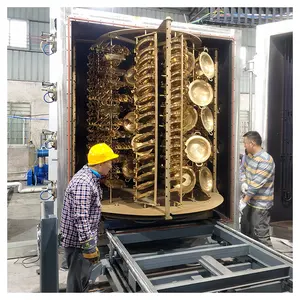

Introduction to PVD Chrome Machines

Physical Vapor Deposition (PVD) chrome machines represent a specialized category of equipment designed for coating metal surfaces with a thin film. This advanced technology is utilized to enhance the durability and aesthetic appeal of metal products without the bulkiness associated with traditional coating methods. PVD chrome machines are integral in industries where precision and resilience are paramount.

Types and Applications

The versatility of PVD coating equipment allows for its application across various sectors. From automotive components to hardware tools, these machines cater to a broad spectrum of metal coating needs. The types of PVD machines include sputtering systems, evaporation coaters, and arc deposition equipment, each serving distinct functions and suited for different coating operations.

Features and Materials

A PVD chrome machine is characterized by its ability to deposit a range of materials, including chrome, titanium, and nickel, onto substrates with precision. The machines are engineered to operate under vacuum conditions, ensuring a clean and controlled environment for high-quality coatings. The use of durable materials in the construction of these machines ensures longevity and consistent performance.

Advantages of PVD Chrome Coating

The application of PVD technology in chrome machines offers numerous advantages. The process is environmentally friendly, producing coatings free from hazardous by-products. Moreover, PVD coatings are known for their exceptional hardness and wear resistance, which significantly extends the lifespan of the coated products. The thin-film deposition also allows for intricate designs without altering the dimensions of the component.

Choosing the Right Machine

Selecting the appropriate metal coating machinery is crucial for achieving desired outcomes. Factors to consider include the substrate material, desired coating thickness, and specific application requirements. Alibaba.com hosts a diverse array of PVD machines, from compact models suitable for small-scale operations to industrial-grade systems for high-volume production.

Integration with Production Lines

Incorporating a vacuum coating machine into existing production lines can streamline the coating process, enhancing efficiency and throughput. These machines can be easily integrated with automated systems, allowing for seamless operation within high-tech manufacturing environments. The adaptability of PVD machines makes them a valuable addition to any production facility focused on metal finishing.