Popular in your industry

Top categories

About pvc compression mould

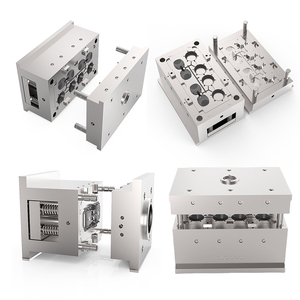

Introduction to PVC Compression Moulds

PVC compression moulds are pivotal in the manufacturing sector, serving as a cornerstone for producing a myriad of PVC-based products. These moulds are designed to shape plastic materials through a compression process, where heated plastic is inserted into a mould cavity and then cooled to form the desired shape. The versatility of pvc compression mould technology allows for the creation of intricate designs, from small functional components to larger decorative elements.

Types and Applications

The application of pvc compression moulding spans various industries, including construction, automotive, and medical sectors. Moulds can range from simple, single-cavity forms to complex, multi-cavity configurations for high-volume production. The adaptability of these moulds means they can be tailored for specific applications, such as creating bolection moulds for architectural embellishments or precision parts for technical equipment.

Material and Design Considerations

When selecting a pvc compression mould, material choice is crucial. Options include iron and other robust materials that ensure durability and longevity of the mould. Design intricacies are paramount, as the mould must precisely mirror the intended product's specifications. This often involves creating prototypes to ensure the mould's accuracy and functionality.

Features and Advantages

A significant advantage of utilizing pvc moulds is the cost-efficiency in mass production. Standardizing certain elements of the mould, such as lift bars, connection sizes, and clamp slots, can further reduce production costs and enhance compatibility across various moulding machines. Moreover, the precision of pvc compression moulds leads to consistent product quality and repeatability in manufacturing processes.

Choosing the Right Mould

Selecting the appropriate pvc compression mould involves considering the design complexity, material, and intended use. Suppliers on Alibaba.com offer a diverse range of moulds to meet these needs. It is essential to communicate specific requirements to ensure the mould aligns with the product's design and functionality demands.

Streamlining Production with PVC Moulds

Incorporating pvc compression moulds into production lines can streamline operations and enhance efficiency. By choosing the right mould for your project on Alibaba.com, you can optimize your manufacturing process, ensuring a smooth transition from design to final product.