Popular in your industry

Related Searches:

Top categories

About pu gasket machine

A PU gasket machine is an intricate device engineered for crafting polyurethane gaskets, essential for sealing functions in diverse sectors. Renowned for their precision and efficiency, these machines incorporate cutting-edge technology to guarantee the production of superior gaskets. The PU gasket dispensing machines are especially prized in industries where robust and dependable sealing solutions are critical. Explore a broad array of PU gasket machines at Alibaba.com.

Types and Characteristics of PU Gasket Machines

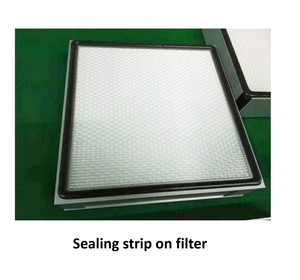

The PU foam gasket machine range includes various models, each designed to meet distinct production requirements. Some are built for high-volume manufacturing, fitting for expansive industrial settings, while others are more compact, perfect for smaller enterprises or field repairs. Certain machines are crafted for precision gaskets in HEPA air filters, while others cater to broader sealing needs in the automotive or appliance industries. These machines differ in features, with some prioritizing rapid production and others focusing on intricate gasket dimensions and patterns.

Structure and Operation of PU Gasket Machines

The architecture of a PU gasket machine is a testament to engineering prowess, comprising several integral components that function harmoniously. The motor, the system's powerhouse, is complemented by a Programmable Logic Controller (PLC) that orchestrates the dispensing process with exactitude. The motor propels the pressure vessel, tasked with sustaining the requisite pressure for gasket formation. Bearings facilitate smooth mechanics, while gears and gearboxes efficiently transmit power. Each element is meticulously calibrated for seamless operation, culminating in an exceptionally productive gasket fabrication process.

Materials and Properties in PU Gasket Machines

The materials chosen for PU gasket machines are lauded for their resilience and efficacy. Polyurethane foam, the primary substance for the gaskets, is selected for its superior sealing capabilities, resistance to degradation, and adaptability to various temperatures and chemicals. The machinery's components are generally composed of premium metals and composites, ensuring durability and the capacity for sustained industrial use with minimal maintenance.

Business Usages and Applications of PU Gasket Machines

PU gasket dispensing machines are integral to a multitude of commercial environments. In the automotive realm, they forge seals that inhibit fluid leakage and muffle sound. Within the construction industry, they ensure insulation and sealing around fenestrations. For electronics, they safeguard enclosures and shield delicate components from particulates and moisture. These machines enhance product longevity, elevate performance, and diminish the frequency of repairs and replacements, thereby creating value.

Functions and Tasks of PU Gasket Machines

The principal role of a PU gasket machine is to fabricate gaskets capable of forming tight seals and enduring diverse environmental conditions. These machines adeptly mix polyurethane ingredients, dispense the blend into molds, and cure the gaskets to the desired firmness. They are adjustable to yield gaskets of varying dimensions and configurations, rendering them versatile instruments in the production continuum.

Features and Unique Selling Points of PU Gasket Machines

Salient features of PU foam gasket machines include their high-precision dispensing mechanisms, energy-conserving operations, and sustainable designs. These units often boast touch screen interfaces for straightforward programming, automated dispensing systems that curtail material excess, and rapid-change tooling for alternating gasket styles. Their unique selling propositions stem from their fusion of speed and accuracy, ensuring each gasket adheres to exacting quality benchmarks.

Benefits and Positive Outcomes of PU Gasket Machines

Employing a PU gasket dispensing machine yields a plethora of advantages, such as diminished labor expenses through automation, uniform product caliber, and the capacity to fulfill large-scale demands with relative ease. For enterprises, this equates to augmented productivity, reduced material wastage, and an enhanced investment return. For end-users, it signifies a product that delivers consistent performance over time, contributing to the durability and efficiency of the equipment or products incorporating the gaskets.

How to Operate and Maintain a PU Gasket Machine

Effectively operating a PU gasket machine entails configuring the apparatus according to gasket specifications, loading the polyurethane material, and programming the PLC for the intended output. Maintenance generally involves routine cleansing of the dispensing nozzles, inspecting for wear on moving parts, and keeping the software current. When choosing the appropriate model, businesses should weigh the volume of gaskets required, the intricacy of the designs, and the space allocated for the machine. Installation typically necessitates a technician's expertise to ensure precise calibration and integration into the existing production framework.

Target Audience and Meeting Needs with PU Gasket Machines

The target demographic for PU foam gasket machines spans sectors in need of robust sealing solutions, such as automotive, aerospace, electronics, and construction. These machines are customized to satisfy the specific demands of these industries by offering adaptable gasket production that conforms to each sector's unique requirements. Whether it's crafting hermetic seals for vehicle parts or weather-resistant gaskets for buildings, these machines deliver the versatility and precision that industry professionals require.

How to Choose the Right PU Gasket Machine?

When selecting a PU gasket machine, factor in the gasket types required, the materials they will consist of, and the anticipated production volume. Opt for machines with a solid track record of dependability and assess the availability of after-sales support. It's also crucial to select a machine that aligns with the voltage and power specifications of your facility.

What are the key selling points of a PU Gasket Machine?

The key selling points of a PU gasket machine encompass its operational efficacy, meticulousness in gasket crafting, and the versatility to produce an array of gasket sizes and shapes. These machines are also esteemed for their extended operational life and the manufacturer's support, which includes technical aid and parts availability.

What after-sales services are available for PU Gasket Machines?

After-sales services for PU gasket machines typically encompass online assistance, video technical support, and the provision of engineers for international service. Some manufacturers also extend field maintenance and repair services, ensuring swift resolution of any issues to minimize operational interruptions.