Popular in your industry

Related Searches:

Top categories

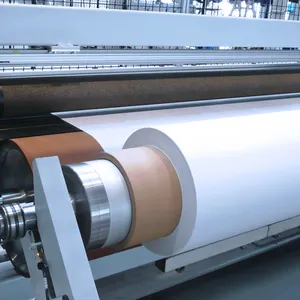

About pp pe fibrillated yarn extrusion line

Introduction to PP PE Fibrillated Yarn Extrusion Lines

The PP PE fibrillated yarn extrusion line is a sophisticated assembly designed for the production of fibrillated yarns, which are widely used in various industries. This type of extrusion line is engineered to process polypropylene (PP) and polyethylene (PE) materials, transforming them into high-strength, versatile yarns suitable for a multitude of applications.

Types and Configurations

Extrusion lines for PP PE fibrillated yarn are available in different configurations, catering to a range of production requirements. The primary distinction lies between single screw and twin screw extruders. Twin screw extruders are known for their enhanced mixing capabilities and higher output rates, making them suitable for large-scale production. Single screw extruders, on the other hand, are valued for their simplicity and cost-effectiveness, ideal for smaller-scale operations.

Applications of Fibrillated Yarns

Fibrillated yarns produced by these extrusion lines are integral to numerous sectors. They are commonly used in the manufacturing of ropes, agricultural twines, artificial turf, and various textiles. The durability and adaptability of these yarns make them a preferred choice for products that require high tensile strength and resistance to environmental factors.

Features and Advantages

A PP PE yarn extrusion machine is designed with features that promote efficiency and reliability. These include advanced temperature control systems for consistent melting and precise die heads for uniform yarn thickness. The advantage of using such specialized machinery lies in its ability to produce consistent quality yarns with excellent mechanical properties, which are essential for the performance of the final products.

Materials and Sustainability

The plastic yarn extrusion process not only utilizes virgin PP and PE but also accommodates recycled materials. This capability is crucial for companies aiming to implement sustainable practices by incorporating recycled plastics into their production cycles, thereby contributing to environmental conservation.

Choosing the Right Extrusion Line

Selecting the appropriate extrusion line for PP PE yarn involves assessing the material compatibility, production capacity, and the specific end-use of the yarn. It is important to consider the technical specifications of the extrusion line to ensure it meets the desired efficiency and output requirements without compromising on the quality of the fibrillated yarns.

Incorporating a PP PE fibrillated yarn extrusion line into your production can significantly enhance your manufacturing capabilities. While exploring the options on Alibaba.com, focus on the machine's features, output rates, and adaptability to your specific production needs to make an informed decision.