A pallet rack roll forming machine is an intricately engineered piece of industrial machinery tailored to fabricate the various elements of pallet racking systems. These systems are indispensable for the streamlined storage and management of goods in warehouses, distribution hubs, and production plants. The machine streamlines the conversion of metal sheets into beams, uprights, and braces, which are fundamental components of a pallet rack.

Types and Applications of Pallet Rack Roll Forming Machines

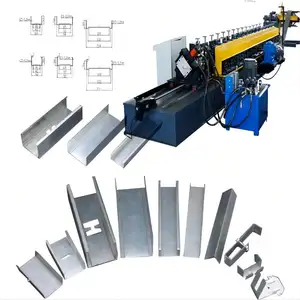

The pallet rack roll forming machine category includes a range of models, each designed with specific features to fulfill distinct roles in the production of pallet racking systems. Certain machines are fine-tuned for crafting uprights with exacting hole-punching precision, vital for adjustable shelving systems. Others are engineered to fabricate beams capable of bearing substantial loads, incorporating reinforced designs. Additionally, specialized machines exist for the creation of shelving decks, necessitating a unique roll forming technique to produce a flat surface with embossed patterns for enhanced strength. These variations facilitate tailored rack configurations, meeting the varied storage requirements of facilities that accommodate items from light consumer goods to hefty industrial machinery.

Structure and Core Components

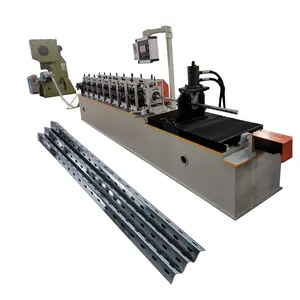

The pallet rack roll forming machine is a composite of multiple mechanical parts that operate in unison. At its heart is a sturdy frame that anchors the entire mechanism. Affixed to this frame are the uncoiler, which dispenses the metal sheet, and the straightening unit, which ensures the material is even and primed for processing. The roll forming station, with its sequence of rollers, progressively molds the metal into the designated profile. Subsequently, the cutting unit, typically equipped with high-precision Cr12Mov steel blades, slices the shaped metal to precise dimensions. Lastly, the punching unit, which may be integrated or a separate entity, perforates the necessary holes or slots as dictated by the design. These components' operations are orchestrated by a sophisticated control system, usually PLC-based, which meticulously directs the machine's functions.

Materials and Durability

The selection of materials for constructing a pallet rack roll forming machine is pivotal to its efficacy and lifespan. The machine's framework is composed of high-grade steel, providing the essential stability and support for the roll forming activity. Rollers and cutting blades, which directly interact with the metal sheets, are typically fashioned from durable tool steels like Cr12Mov, renowned for their resistance to wear. These materials are chosen not only for their robustness but also for their capacity to maintain accuracy across countless production cycles, guaranteeing uniform quality in the output of pallet rack components.

Business Usages and Applications

In the commercial sphere, the pallet rack roll forming machine is utilized across diverse sectors. Within manufacturing, it enables the bespoke creation of storage systems, allowing factories to maximize spatial efficiency and refine inventory control. Retail distribution centers employ these machines to construct racking systems that can support an extensive array of merchandise, thus optimizing logistical operations. The construction industry also gains from the machine's ability to produce solid structural elements, crucial for the development of large-scale storage edifices. By expediting the production of pallet racks, these machines aid businesses in curtailing expenses, augmenting storage capacity, and enhancing the systematic arrangement of products.

Functions and Capabilities

The primary role of a pallet rack roll forming machine is to transmute metal sheets into diverse structural parts of a pallet rack system. It executes a suite of operations including roll forming, cutting, and punching with exactitude. The apparatus is adept at managing various metal gauges and widths, facilitating the manufacture of an array of racking components. Advanced iterations can even undertake multiple tasks concurrently, such as crafting different profiles in a single pass, markedly boosting productivity.

Features and Unique Selling Points

Notable attributes of the pallet rack roll forming machine encompass its rapid production rates and the integration of cutting-edge technologies such as remote monitoring and operational control. These attributes permit manufacturers to escalate output while preserving quality standards. The machine's versatility in processing diverse material types and its energy-efficient operation are also salient features that distinguish it from the competition. Moreover, the inclusion of intuitive interfaces and automated systems diminishes the necessity for specialized labor, rendering it a cost-effective option for enterprises seeking to minimize workforce expenses.

Benefits and Advantages

The pallet rack roll forming machine proffers a multitude of advantages to its operators. It delivers a high degree of automation, which translates into reduced manual labor and diminished production costs. The machine's output is characterized by precision and uniformity, resulting in top-tier racking components that ensure the end storage systems are both reliable and enduring. For businesses, this equates to enhanced storage efficiency and an improved investment return. The machine's robust build and the use of superior materials also mean it demands less upkeep, offering sustained value over time.

How to Choose the Right Machine?

Choosing the suitable pallet rack roll forming machine entails evaluating your production requirements, including the types of racking elements needed, the desired output volume, and the specific material criteria. It's crucial to consider the machine's compatibility with the intended product assortment and its flexibility to adapt to potential shifts in product design. Assessing the machine's level of automation, operational speed, and precision will further assist businesses in selecting a model that aligns with their production objectives.

How to Maintain Optimal Performance?

To guarantee the pallet rack roll forming machine functions at peak efficiency, consistent maintenance is vital. This encompasses regular checks, prompt replacement of components showing wear, and adherence to the manufacturer's recommended service intervals. Ensuring moving parts are well-lubricated and the apparatus is kept free from debris and dust also contributes to optimal performance. Equally important is the training of operators in proper usage and troubleshooting techniques to avert unnecessary halts in production.

What After-sales Services Are Available?

Following the acquisition of a pallet rack roll forming machine, purchasers can avail themselves of a comprehensive array of after-sales services. These services include on-site setup and commissioning, alongside instructional sessions for machine operators. Technical assistance is accessible through various means, such as video calls and online support, ensuring swift resolution of operational challenges. For international clientele, the presence of local service centers offers the convenience of prompt and culturally responsive support.

Discover the broad assortment of pallet rack roll forming machines on Alibaba.com to identify the apparatus that meets your enterprise's requirements and benefit from the extensive after-sales services provided.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4