Popular in your industry

Related Searches:

Top categories

About injection mold iran

Introduction to Injection Mold Iran

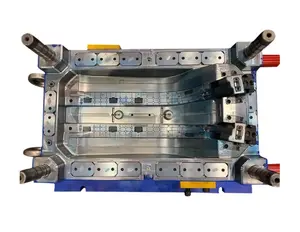

Injection molding is a pivotal manufacturing process used across industries for producing a vast array of items. Within the realm of injection mold Iran, the focus is on crafting precision molds that cater to diverse applications, from intricate components to larger, aesthetic pieces. This process involves injecting molten materials into a mold, which then cools and solidifies into the final product.

Types and Applications

The versatility of injection molding services is evident in the variety of molds available. From small, complex items essential in the electronics industry to larger molds used for creating decorative elements such as bolection molds for door plating, the applications are extensive. The adaptability of the process allows for its use in automotive, medical, consumer goods, and many other sectors, demonstrating the expansive reach of injection mold products.

Material Selection and Features

Selecting the appropriate material for a mold is crucial, with options ranging from robust iron to innovative composites. The choice of material impacts the mold's durability, cycle time, and the quality of the finished product. Features such as thermal resistance and surface finish are also critical considerations that influence the performance of an injection mold. The intricacies of design and material selection underscore the technical expertise available through the platform.

Advantages of Standardization

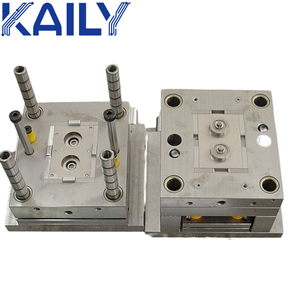

Optimizing production efficiency is a key benefit of standardizing certain elements of an injection mold. By harmonizing components like lift bars, connection sizes, and clamp slots, manufacturers can streamline operations and enhance compatibility across various molds. This approach not only simplifies the molding process but also potentially reduces future production costs.

Ensuring Mold Precision

Precision is paramount in injection molding. Specialists in injection mold fabrication work diligently to refine molds, conducting multiple tests to ensure each mold meets the exact specifications required. This meticulous process of validation ensures that the final output aligns with the client's expectations, emphasizing the commitment to precision within the injection mold industry.

Finding the Right Injection Mold Partner

Navigating the selection of an injection mold supplier is streamlined on Alibaba.com. The platform facilitates connections between buyers and experienced suppliers, ensuring a comprehensive understanding of the requirements and capabilities. Utilizing the detailed information provided, buyers can make informed decisions to meet their specific injection mold needs.