Understanding High Temperature Barcode Labels

High temperature barcode labels are specialized identification tools designed to withstand extreme heat conditions without degrading. These labels are crucial for tracking assets, managing inventory, and ensuring the safety of products that are exposed to high-temperature environments. Their durability and resistance to heat make them an essential component in various industrial applications.

Types and Materials

There are several types of high temperature barcode labels, each tailored to different heat thresholds and environments. Materials commonly used for these labels include polyimide, ceramic, and other heat-resistant substrates. These materials ensure that the labels maintain their structural integrity and readability even when subjected to high temperatures.

Applications of High Temp Barcode Labels

High temp barcode labels are utilized in a multitude of sectors, including manufacturing, aerospace, automotive, and electronics. They are particularly valuable for tracking components that undergo high-heat processes such as autoclaving, PCB manufacturing, and engine parts management. The resilience of these labels ensures reliable scanning and data collection throughout the product's lifecycle.

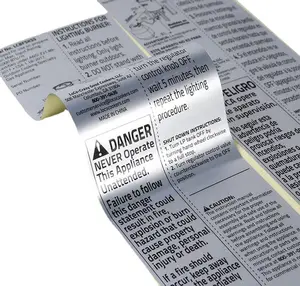

Features and Advantages

The features of high temperature barcode tags include their ability to resist smudging, fading, and adhesive degradation at elevated temperatures. This resilience provides a clear advantage in maintaining legibility and adhesion over time, which is critical for effective asset management and safety compliance in heat-intensive industries.

Choosing the Right Label

Selecting the appropriate heat resistant barcode labels involves considering the specific temperature range they will be exposed to and the surface they will be adhered to. It is important to match the label material and adhesive properties with the application's requirements to ensure optimal performance.

Environmental and Safety Considerations

In addition to heat resistance, it is essential to consider the environmental factors such as exposure to chemicals or abrasion that may affect the label. Safety is also paramount, as the use of high temperature barcode labels can contribute to safe handling and usage of high-heat products and components.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4