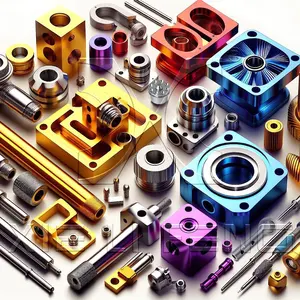

Exploring High Demand CNC Parts

CNC (Computer Numerical Control) parts are integral components in modern manufacturing, catering to a variety of industries from aerospace to automotive. The category of high demand CNC parts encompasses a range of precision-engineered components that are essential for complex machinery and intricate designs. These parts are crafted through a meticulous process of machining, which includes various techniques such as milling, grinding, and drilling.

Types and Applications of CNC Machining

The versatility of CNC machining allows for the production of parts in diverse shapes and sizes. This process is not limited to a single type of material, making it suitable for a wide array of applications. From small-scale components to large industrial machinery, CNC parts are pivotal in ensuring the seamless operation and longevity of equipment. The adaptability of these parts makes them suitable for custom projects, where specificity in dimensions and tolerances is paramount.

Features and Materials

CNC precision machining is characterized by its ability to produce parts with exceptional accuracy. The materials used in the production of these parts vary, including metals like aluminum and steel, as well as plastics and composites. Each material is chosen based on its properties, such as strength, thermal resistance, and electrical conductivity, to meet the specific needs of the application.

Advanced Machining Techniques

In the realm of CNC manufacturing, advanced techniques such as EDM (Electrical Discharge Machining) are employed. EDM is a non-traditional method that uses electrical sparks to shape materials, offering an alternative to traditional cutting methods. This technique is particularly useful for materials that are difficult to machine with conventional tools. Additionally, specialized cutting options like tube laser cutting provide precise edges, which are crucial for components requiring high accuracy.

Advantages of CNC Machined Parts

The advantages of CNC machined components are numerous. They offer unparalleled precision, which is critical in industries where even the slightest deviation can lead to significant issues. The efficiency of CNC machining also allows for rapid production, which is essential in meeting the demands of fast-paced markets. Furthermore, the flexibility in material choice and machining techniques ensures that each part can be tailored to the specific requirements of the project.

Choosing the Right CNC Machining Services

Selecting the appropriate service for custom CNC parts is crucial. It involves understanding the intricacies of the design and the functional requirements of the part. Experts in CNC machining can provide valuable insights into the best approach for creating a tangible product. With a focus on precision and adherence to design specifications, these services strive to deliver components that align with the client's expectations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4