Popular in your industry

Top categories

About double corner cutting machine

Introduction to Double Corner Cutting Machines

The double corner cutting machine is an essential piece of equipment for businesses involved in the production of paper-based products such as toilet papers, napkins, and other disposable items. This machinery is a staple in the paper processing industry, catering to the needs of various sectors including hospitality, manufacturing, and paper mills.

Types and Applications

There are diverse models of corner cutter machines designed to meet different production demands. From compact units suitable for small-scale operations to robust machines for high-volume production, these machines are versatile. Their applications span across creating precise cuts for paper cups, serviettes, and tissues, with each machine offering a range of functionalities from embossing to color printing.

Features and Functionality

A typical paper corner cutter is equipped with multiple units that work in unison to deliver a finished product. These units include embossing, which can be done with various patterns using steel-to-steel or steel-to-rubber configurations, slitting, folding, counting, and stacking. Automation is a key feature, with many machines boasting gear or chain driving systems, automatic oil lubrication, and photoelectric technology for operational monitoring.

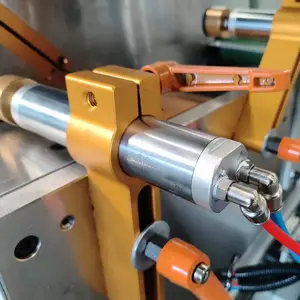

Materials and Construction

The construction of a corner cutting machine involves heavy-duty materials capable of withstanding the rigors of industrial use. The machines are generally made from high-grade steel and incorporate components designed for efficiency and durability. The use of photoelectric sensors and PLC control panels underscores the technological sophistication of these machines.

Advantages of Modern Machines

Modern corner cutters offer significant advantages in terms of production capacity and automation. Small machines can handle 70 to 80 pieces per minute, while larger variants can manage up to 3 tons of output per day. The integration of PLC control panels in these systems facilitates a fully automatic operation, enhancing productivity and reducing the need for manual intervention.

Choosing the Right Machine

Selecting the right double corner cutting machine depends on the scale of production and specific operational requirements. Factors such as machine weight, power usage, and production capacity are crucial considerations. Prospective buyers should assess the specifications of each machine to find the one that aligns with their operational goals and production targets.