Understanding Custom Heatpipe Coolers

Custom heatpipe coolers are specialized components designed for effective thermal management across various industries. These devices play a crucial role in systems where temperature regulation is critical, such as in power generation, chemical processing, and even residential heating solutions. By leveraging the principles of thermodynamics, heatpipe coolers facilitate the transfer of heat from one point to another, ensuring optimal operating temperatures and enhancing the efficiency of thermal systems.

Types and Applications

The versatility of heatpipe technology allows for its application in diverse settings. Industrial heat exchangers, a category to which custom heatpipe coolers belong, are integral to operations in power plants and chemical processing facilities. Their use is also prominent in sectors like biofuel production, transportation, cryogenics, and food processing. In residential contexts, these coolers contribute to more efficient air conditioning and water heating systems.

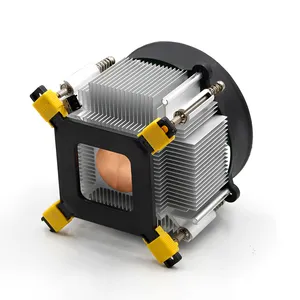

Material Advantages and Features

Materials used in the construction of heatpipe coolers, such as copper, stainless steel, and titanium, are selected for their thermal conductivity and durability. Copper heat exchangers, for instance, are known for their corrosion resistance and are often used in systems involving potable water due to their antimicrobial properties. Stainless steel variants are prized for their rapid heat transfer capabilities, making them suitable for large-scale water treatment. Titanium heatpipe coolers offer high-temperature resistance and are indispensable in high-stakes environments where failure is not an option.

Customization and Efficiency

Customization is at the heart of heatpipe solutions, with options ranging from shell and tube to plate heat exchangers. Each design caters to specific industry requirements, such as climate control in beer production or specialized models for mining operations. Custom heatpipe coolers are also available for less intensive applications, providing efficient thermal management in home and office settings.

Selection Considerations

When selecting a custom heatpipe cooler, it is essential to consider the specific needs of the application. Factors such as the operating environment, temperature extremes, fluid types, and flow rates must be taken into account. The choice between different models, such as shell and tube or plate exchangers, should be informed by these operational parameters to ensure the chosen cooler meets the system's requirements without over-specifying.

Environmental Impact and Sustainability

In an era where environmental sustainability is paramount, thermal management systems must not only be effective but also environmentally conscious. Custom heatpipe coolers are designed to optimize energy consumption and reduce waste heat, contributing to more sustainable industrial practices and lower energy costs in residential heating and cooling systems.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4