Popular in your industry

Related Searches:

Top categories

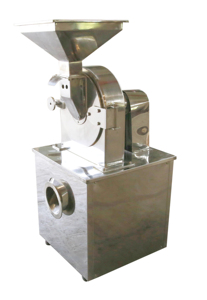

About cryogenic food grinder

Introduction to Cryogenic Food Grinders

Cryogenic food grinders represent a revolutionary approach in the processing of food materials. Utilizing extremely low temperatures, these grinders are designed to pulverize a variety of food products, enhancing both the quality and the fineness of the ground particles. This category of grinding equipment is essential for operations that require the milling of spices, herbs, and other foodstuffs that are sensitive to heat.

Types and Applications

The versatility of cryogenic grinding equipment extends to various types, each suited for specific applications. From batch to continuous systems, these grinders serve a multitude of industries, including culinary, pharmaceutical, and chemical sectors. The application of such technology ensures that the material's essential properties, like flavor and color, are preserved while achieving the desired consistency.

Features and Materials

A cryogenic milling system is characterized by its ability to use liquid nitrogen or other cryogens to cool materials before and during the grinding process. Constructed from robust materials compatible with low temperatures, these grinders are engineered to operate efficiently within a cryogenic environment, ensuring the integrity of both the machinery and the product.

Advantages of Cryogenic Grinding

The primary advantage of a cryogenic grinder lies in its ability to produce finer particles with more uniformity than traditional grinding methods. Additionally, the low-temperature process minimizes the loss of volatile components, resulting in higher quality ground products. This method also reduces the risk of thermal degradation of the material, making it ideal for heat-sensitive substances.

Operational Efficiency

Efficiency in particle size reduction is critical, and cryogenic grinding technology offers superior performance in this aspect. The cold environment ensures that materials become brittle and fracture more easily, leading to a more efficient grinding process. This efficiency is not only beneficial for the quality of the end product but also contributes to the longevity of the grinding equipment.

Choosing the Right Cryogenic Food Grinder

Selecting the appropriate cryogenic food processing equipment is crucial for meeting specific production needs. Alibaba.com showcases a diverse array of grinder models to cater to various operational scales and requirements. Prospective buyers can explore detailed information on each product, ensuring an informed decision without the influence of promotional content.