Introduction to Cotton Filter Machines

Cotton filter machines are integral components in the textile and purification industries, designed to enhance the efficiency of nonwoven bag production and other filtration applications. These machines are engineered to streamline production processes, ensuring a balance between speed and quality in output.

Types and Applications

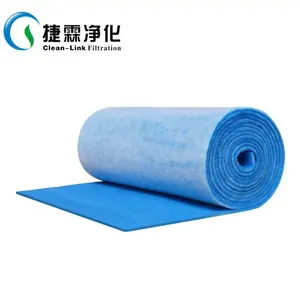

The versatility of cotton filter machines is reflected in their various models and sizes, catering to a wide range of production demands. From small-scale operations to large manufacturing facilities, these machines play a pivotal role in the creation of filters used in agriculture, automotive, and air and water purification systems.

Features and Materials

Constructed with robust materials, cotton filter machines are built to last. They boast features that promote ease of use, such as user-friendly control panels and automated monitoring systems. These features allow for precise adjustments to production parameters, ensuring the consistency of the final products.

Advantages of Modern Cotton Filter Machines

Modern cotton filter machines are designed with efficiency in mind, equipped with automation that aids in maintaining uniformity across products. The integration of safety features also minimizes the risk of operator injury, highlighting the user-centric design of these machines.

Operational Efficiency

The operational efficiency of a cotton filter machine is a key factor in its value to a production facility. With the ability to set and forget production parameters, these machines contribute to a seamless production flow, which is crucial for meeting both deadlines and quality standards.

Choosing the Right Machine

Selecting the appropriate cotton filter machine is essential for optimizing production. Factors such as output requirements, space constraints, and the specific type of filtration media being produced should guide the decision-making process, ensuring that the machine aligns with the facility's operational goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4