Introduction to Concrete Fascia Board

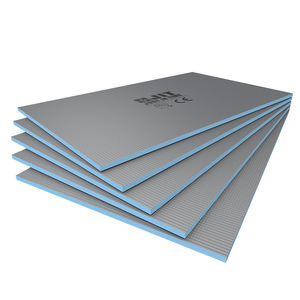

Concrete fascia boards are essential components in both residential and commercial construction, serving as robust, long-lasting backing surfaces for tile and other finishes. These boards are crafted from a blend of fiber cement, creating sheets that provide critical support and protection for wall and ceiling installations.

Types and Applications

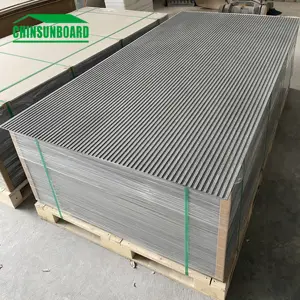

The versatility of concrete fascia board allows for its use in various settings. Interior applications typically involve concrete backer boards, which are indispensable in moisture-prone areas like bathrooms and kitchens. For exteriors, concrete roof fascia offers a durable and maintenance-friendly option, ensuring that the edging of roofs withstands environmental elements effectively.

Features and Materials

Constructed from a composite of fiber cement, these boards are engineered to resist water, preventing the growth of mold and the deterioration that water damage can cause. This resistance makes concrete fascia board a more robust choice than gypsum-based alternatives, especially in damp or outdoor environments.

Advantages of Concrete Fascia Board

The primary advantage of using concrete fascia board lies in its durability and resistance to elements that typically harm other materials. Unlike other substrates that may warp or rot, fiber cement boards maintain their integrity over time, making them a wise choice for long-term construction projects.

Installation Considerations

While installing concrete fascia board, it is crucial to address the seams properly. The use of cement board tape is recommended to ensure that the joints between boards are sealed, preventing moisture ingress and contributing to the overall stability of the tiled surface.

Choosing the Right Product

Selecting the appropriate concrete fascia board for a project is vital. Factors such as the specific application, environmental conditions, and the type of finish being applied should guide the selection process. The platform offers a diverse range of options to cater to different project requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4