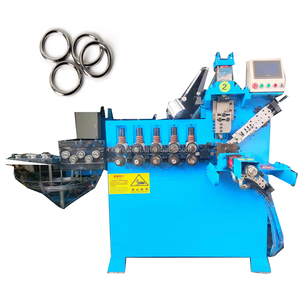

Introduction to Coil Welding Machines

Coil welding machines are integral components in the fabrication and repair of metal structures and parts. These devices facilitate the joining of metals with precision and strength, catering to a variety of industrial and commercial applications. The coil welding machine category encompasses a range of equipment designed to meet diverse welding needs, from intricate electronic components to robust construction projects.

Types and Technologies

The versatility of coil welding machines is evident in the array of technologies they employ. Users can select from welding machine coil types such as Metal Inert Gas (MIG), Tungsten Inert Gas (TIG), IGBT inverter, and Manual Metal Arc (MMA) welding. Each technology offers unique benefits, making them suitable for specific metals like stainless steel, carbon steel, copper, and aluminum. Multi-functional machines serve as plasma cutters, TIG welders, and stick welders, providing comprehensive solutions for various welding tasks.

Features and Specifications

A coil welder is typically equipped with an electrode holder, earth clamp, and power cable, ensuring that all necessary components are at hand for immediate operation. These machines operate within a voltage range of 110 to 380 volts and are compatible with 50/60 HZ power supplies, making them adaptable to most domestic power units. The output current of these machines can range from 20 to 300A, with power capacities reaching up to 8 KVA. The precise control of the welding process is facilitated by a digital display that indicates the current level.

Design and Portability

The design of coil welding machines emphasizes portability and ease of use. Weighing between 4kg and 20kg, these machines are light enough to be transported around various workstations. The choice between DC and AC motors allows for customization based on the specific application, enhancing the machine's versatility. For those requiring equipment for limited space, a coil welding machine single phase option is available, offering a compact solution without compromising performance.

Safety and Stability Features

Safety is paramount in welding operations, and modern coil welding machines incorporate intelligent features to ensure stable and secure use. An automatic switching chip is designed to detect voltage levels and adjust the settings to prevent over and under-voltage situations. This also protects the machine against overheating. Additionally, an in-built arc force increases the output current to maintain a stable arc, while a hot start mechanism prevents electrode sticking during the initiation of the arc.

Applications and Advantages

The application of copper coil welding machines extends across various industries, from automotive to construction, where the welding of copper coils is prevalent. The advantages of using these specialized machines include enhanced joint quality, increased productivity, and the ability to handle a range of metal types and thicknesses. Whether for business needs or DIY projects, Alibaba.com presents a selection of welding coil machines to cater to specific welding requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4