Popular in your industry

Top categories

About cip system sintering furnace

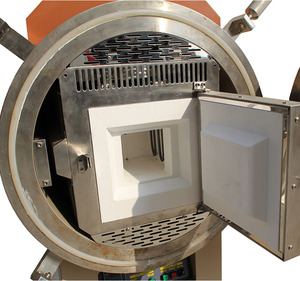

Introduction to CIP System Sintering Furnaces

Sintering furnaces are pivotal in the manufacturing process, where powder materials are transformed into a solid mass through heat and pressure—a process known as sintering. The CIP system sintering furnace, standing for Cold Isostatic Pressing, is a specialized type that applies equal pressure in all directions on the material to achieve uniform density and size. This category of furnaces is essential in industries such as aerospace, automotive, and dental for creating complex parts.

Types and Applications

There are various types of sintering furnaces, each suited to specific applications. The industrial sintering furnace is designed for large-scale production, handling high volumes with consistent results. In contrast, the laboratory sintering furnace is used for research and development, allowing for precise control and experimentation. Applications range from metal part fabrication to ceramic production, highlighting the versatility of these systems.

Features and Materials

A high-temperature sintering furnace is characterized by its ability to reach extreme temperatures, essential for sintering high-melting-point materials like tungsten and molybdenum. The construction materials of these furnaces, such as advanced ceramics and refractory metals, are chosen for their durability and heat resistance. The design of a vacuum sintering furnace ensures a controlled atmosphere, crucial for maintaining the purity of the final product.

Advantages of CIP System Sintering Furnaces

The CIP system sintering furnace offers several advantages. Its ability to apply uniform pressure ensures consistent product quality, while the controlled atmosphere minimizes oxidation and contamination. The precision of a digital sintering furnace allows for fine-tuning of temperature and pressure, leading to improved material properties and performance of the sintered parts.

Considerations for Selection

When selecting a CIP system sintering furnace, consider the material to be sintered, the desired throughput, and the level of control required. The size and configuration of the furnace, such as a benchtop sintering furnace, should match the production needs and available space. It's also important to consider the energy efficiency of the system, as sintering can be an energy-intensive process.

Connecting with Suppliers

Alibaba.com serves as a gateway to connect with a diverse range of suppliers offering various sintering furnaces. Whether you're in need of a compact sintering furnace for small-scale production or a robust system for industrial applications, the platform facilitates the sourcing of equipment that meets your specific requirements without direct promotion or guarantees.