Popular in your industry

Related Searches:

Top categories

About card pick and place machine

Introduction to Card Pick and Place Machines

The card pick and place machine is an integral component in the realm of electronic assembly, playing a pivotal role in the efficient production of electronic motherboards, LED lighting systems, digital cameras, and a variety of other consumer electronics. These sophisticated devices are engineered to automate the placement of components onto printed circuit boards (PCBs), ensuring precision and speed in high-volume manufacturing environments.

Types and Applications

Diverse in their capabilities, pick and place equipment ranges from machines tailored for specific tasks such as PCB loading and component soldering to comprehensive systems that incorporate multiple functions within a single unit. The application of these machines spans across the production of intricate electronic devices, where they are indispensable in the precise placement of microchips and other miniature components.

Features and Functionality

A typical surface mount device (SMD) placement machine includes several advanced features. These encompass flux systems for surface preparation, transport systems for PCB mobility, and control interfaces for operational settings. Flux systems are crucial for maintaining the integrity of the soldering process, while transport systems ensure the seamless movement of PCBs through the production line. The control interface allows for meticulous adjustments of various parameters, such as soldering temperature and conveyor speed.

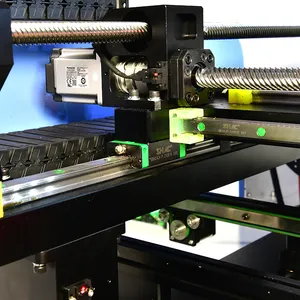

Materials and Construction

The construction of a PCB pick and place machine involves materials and components that ensure durability and reliability. With a framework typically made from robust metals, these machines are designed to withstand the rigors of continuous industrial use. The precision parts within the machine, such as nozzles and feeders, are often crafted from high-grade materials that offer both precision and longevity.

Advantages of Automation in Electronics Assembly

Automation through a PCB assembly machine brings numerous advantages to electronics manufacturing. The ability to place thousands of components per hour with high accuracy reduces the likelihood of human error and increases production throughput. Moreover, the adaptability of these machines to handle various PCB sizes and component types makes them a versatile solution for a wide range of electronic products.

Choosing the Right Machine

Selecting the appropriate automatic pick and place machine is crucial for optimizing production efficiency. Factors such as the machine's speed, which can range from 3,500 to 6,500 pieces per hour, its size, weight, and the specific technologies it employs, should be considered in light of the intended application and production volume. Prospective buyers are encouraged to assess their needs carefully to identify the machine that aligns with their manufacturing objectives.