Popular in your industry

Top categories

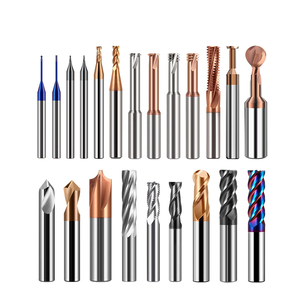

About carbide fresa cnc end mill

Understanding Carbide Fresa CNC End Mills

Carbide fresa CNC end mills are precision cutting tools used extensively in industrial milling operations. Designed to remove material through milling, these end mills are crafted from durable carbide and are integral in shaping a variety of mechanical parts. Unlike standard milling bits that cut in a singular axial direction, carbide fresa CNC end mills boast the capability to cut in both axial and radial directions, enhancing their versatility in complex milling tasks.

Types and Applications

The utility of carbide fresa CNC end mills extends across various industries, including automotive and aerospace, where precision is paramount. The range of axes configurations—from three-axis mills suitable for general purposes to five-axis mills designed for intricate components—demonstrates their adaptability. The three-axis variant offers flexibility in positioning, while four-axis mills feature a turnaround table for more complex operations. The pinnacle of precision, the five-axis mills, incorporate three linear and two rotary axes, adjustable per model, catering to advanced manufacturing needs.

Features and Materials

The construction of carbide fresa CNC end mills is a testament to their robustness and longevity. Carbide, known for its rigidity and resistance to wear, ensures that these end mills maintain their cutting edge under strenuous conditions. The geometry of these mills varies, encompassing cylindrical, conical, and even hemispherical shapes, each tailored to specific milling requirements. This diversity in shape allows for a broad spectrum of milling operations, from simple to complex profiles.

Advantages of Carbide End Mills

Opting for carbide fresa CNC end mills brings several advantages to the milling process. Their hard-wearing nature translates to extended tool life and consistent performance. The ability to operate on multiple axes not only simplifies the production of intricate designs but also reduces the need for multiple setups, streamlining the manufacturing process. Furthermore, the addition of accessories can expand their capabilities even further, making them a valuable asset in any industrial milling setup.

Selection Considerations

When selecting a carbide fresa CNC end mill, it is crucial to consider the specific needs of the milling task at hand. Factors such as the material to be milled, the complexity of the part design, and the required precision all play a role in determining the most suitable end mill type. It is also important to match the end mill to the capabilities of the CNC machine, ensuring that the tool can perform effectively within the machine's operational parameters.

Conclusion

In summary, carbide fresa CNC end mills are a cornerstone in industrial milling, offering a blend of durability, precision, and adaptability. Their design variations cater to a wide range of applications, making them a go-to choice for businesses looking to optimize their milling operations. While the selection of the appropriate end mill requires careful consideration, the payoff in efficiency and quality is substantial.