Introduction to Box Bending Machines

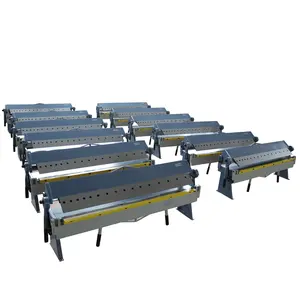

A box bending machine is an essential tool in the metal fabrication industry, designed to enhance productivity and efficiency in bending operations. This equipment is engineered to handle a variety of materials, providing precision and control over the bending process.

Types and Applications

The versatility of a box bending machine extends to its ability to work with different materials and thicknesses. From square tube pipe benders to small box and pan brakes, these machines cater to a range of applications. They are adept at creating precise bends in square tubing, making them ideal for constructing frames and structures. The square tubing bender machine variant is particularly suited for architectural and structural projects.

Features and Materials

Box bending machines are designed with features that promote material conservation and safety. The inclusion of a sheet metal pan brake allows for efficient bending without waste. Additionally, machines equipped with a finger sheet metal brake system enable operators to perform hemming, which safely folds metal edges. This feature is crucial in preventing workplace accidents. The construction of these machines often involves robust materials, ensuring durability and long-term performance.

Advantages of Utilizing Box Bending Equipment

One of the primary advantages of employing a box bending machine is its contribution to reducing metal wastage. The precision of a metal pan brake ensures optimal use of materials. Furthermore, the adaptability of machines like the 48 inch sheet metal brake and the 24 sheet metal brake allows for handling various project sizes with ease. The capability to perform in-house metal bending also cuts down on outsourcing costs and provides better oversight of production quality.

Considerations for Purchase

When considering the acquisition of a box bending machine, factors such as tonnage, bending length, and size are crucial. Tonnage, or bending force, is vital for determining the machine's capability to shape metal. The size of the machine should align with the available workspace, ensuring seamless integration into your operation. Prospective buyers should also evaluate the machine's compatibility with tasks, such as whether a steel square tube bender or a box tube bender is more suitable for their specific requirements.

Conclusion

For businesses seeking to enhance their metalworking capabilities, a box bending machine is a valuable investment. Alibaba.com offers a diverse selection of machines to accommodate various bending needs. Whether you require a baileigh magnetic sheet metal brake or a manual square tubing bender, the platform provides a convenient and efficient way to source your equipment. Explore the options available to find the perfect fit for your metal fabrication needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4