Popular in your industry

Related Searches:

Top categories

About aluminum extrusion profile for suitcase

Exploring Aluminum Extrusion Profiles for Suitcases

Aluminum extrusion profiles for suitcases are integral components in modern luggage design, offering durability and a sleek finish. These profiles are crafted through a process that pushes aluminum through a die, creating cross-sectional shapes that provide the structural framework for suitcases. The versatility of aluminum extrusion allows for a wide range of applications beyond luggage, including automotive, construction, and furniture industries.

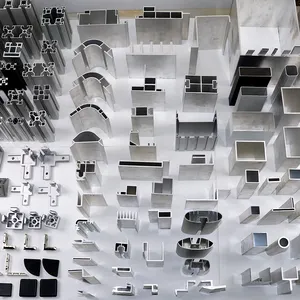

Types and Shapes of Aluminum Profiles

The variety of shapes available in aluminum extrusion profiles for suitcases is vast, with each shape serving a specific function. Common forms include L-angled, square, and T-shaped bars, which contribute to the suitcase's overall stability and shape. Hollow tubes and solid round tubes are also prevalent, often used for handles and structural reinforcements. Additionally, specialized components like J caps, Z clips, and sliding track systems are tailored to enhance the functionality and security of the luggage.

Material Specifications and Customization

Aluminum alloys, particularly from the 6000 series, are predominantly used for these profiles, known for their balance of strength and workability. The temper of these alloys can range from T3 to T8, indicating the level of hardness and strength due to heat treatment. While standard thicknesses range from 0.2mm to 20mm, customization options are available to meet specific design requirements, ensuring that the aluminum profiles can be tailored to various specifications.

Surface Treatments and Finishes

Surface treatment techniques such as powder coating, anodizing, and electrophoresis are employed to enhance the appearance and durability of aluminum suitcase profiles. Anodizing electrically induces an anodic layer that can be colored, providing both aesthetic qualities and corrosion resistance. Electrophoresis builds upon anodizing, adding a glossy sheen to the profile. For a more natural look, wood grain finishes are available, mimicking the texture and appearance of real wood, suitable for decorative purposes.

Advantages of Aluminum Extrusion in Suitcases

The use of aluminum extrusion profiles in suitcase design brings numerous advantages. These profiles offer a high strength-to-weight ratio, essential for maintaining luggage durability while keeping it lightweight. The malleability of aluminum allows for the creation of complex shapes and designs, providing both functional and aesthetic benefits. Furthermore, the corrosion-resistant properties of treated aluminum ensure that the suitcase maintains its appearance over time, even under frequent travel conditions.

Choosing the Right Profile for Your Needs

Selecting the appropriate aluminum extrusion profile for your suitcase involves considering the intended use, desired aesthetic, and required durability. With a multitude of customization options and finishes, the profiles can be tailored to meet a wide array of design preferences. For those in the market for these components, Alibaba.com serves as a hub, connecting buyers with a diverse selection of profiles from reputable suppliers, catering to all your luggage manufacturing needs.