Popular in your industry

Related Searches:

Top categories

About 50 ton forging press

Exploring the Capabilities of a 50 Ton Forging Press

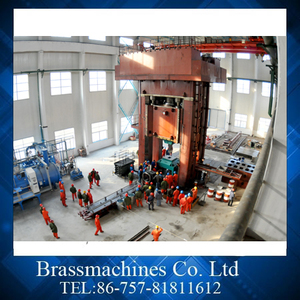

The industrial landscape is dotted with machinery designed for precision and durability, among which the 50 ton forging press stands as a pivotal component. This category encompasses a range of machines engineered for transforming metal into specific shapes and sizes through the application of compressive forces.

Types of 50 Ton Forging Machines

Forging presses are categorized based on their operational axes and mechanisms. The horizontal forging machines are known for their horizontal movement during operation, making them suitable for the finishing and pre-forming of bar stock. On the other hand, vertical forging machines operate with vertical tool movement, which is essential for smaller forgings such as hooks and blanks for edged tools. Another variant within this category is the 50 ton hydraulic forging press, which utilizes hydraulic power for operations requiring precise control and significant force.

Applications and Features

The versatility of the 50 ton forging press is evident in its wide range of applications. From creating intricate parts like propeller blanks to performing hot drawing and swaging, these machines are integral to various manufacturing processes. The mesta 50 000 ton press, a relative of the smaller 50-ton press, exemplifies the scalability of forging technology to accommodate larger projects. Rotary forging machines, a subset within this category, are distinguished by their rotating tools and are instrumental in shaping metals through rotational movements.

Materials and Advantages

Forging presses are designed to handle a plethora of materials, ranging from common metals to specialized alloys. The construction of these machines often involves robust materials to withstand the high-pressure environment of forging. The alcoa 50 000 ton forging press is an example of a machine built to accommodate the specific needs of aluminum forging, showcasing the material-specific design of these presses. The advantages of using a 50 ton forging press include enhanced production rates and the ability to produce complex shapes with precision.

Choosing the Right Forging Press

Selecting the appropriate forging press requires an understanding of the specific requirements of the task at hand. Factors such as the type of material, the complexity of the shapes, and the production volume all play a crucial role in determining the most suitable machine. Whether it is a 50 ton hydraulic forging press for detailed work or a larger press for bulk operations, the choice hinges on the intended application and desired outcomes.

In conclusion, the 50 ton forging press is a versatile and essential machine for metal shaping and forming. With various types available to suit different manufacturing needs, these presses are a testament to the innovation and engineering prowess that drive the industrial sector forward.