Popular in your industry

Related Searches:

Top categories

About 3d cnc foam sculpture machine

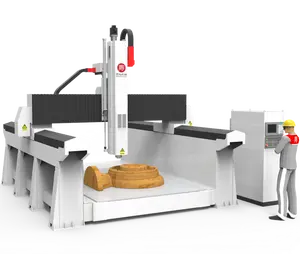

Introduction to 3D CNC Foam Sculpture Machines

The realm of woodworking and sculpting has been revolutionized by the advent of 3D CNC foam sculpture machines. These sophisticated devices are engineered to carve, shape, and create intricate designs in foam, offering a versatile solution for various applications. This category encompasses a broad spectrum of machines tailored to meet the diverse needs of fabricators and artisans.

Types and Applications

The applications of CNC foam cutters are extensive, ranging from artistic sculpting to industrial prototyping. Users can select from an array of machine types, such as industrial-grade CNC routers for large-scale production or compact models suitable for smaller workshops. Each type serves a specific purpose, whether it's crafting detailed architectural models, producing theatrical props, or fabricating intricate molds.

Features and Specifications

A CNC foam milling machine is characterized by its precision and control. Key specifications include the machine's power rating, cutting speed, and table size, which dictate its suitability for certain tasks. Advanced models come with features like multi-axis cutting capabilities, enabling them to execute complex three-dimensional patterns with ease.

Materials and Construction

The construction of a foam carving CNC machine is designed to offer stability and durability. High-grade materials are used to ensure the machine can withstand the demands of continuous operation while maintaining accuracy. The choice of materials also affects the machine's ability to handle different foam densities, from lightweight polystyrene to rigid polyurethane foams.

Advantages of Using CNC Foam Carving Machines

Employing a CNC 3D foam cutting machine in production brings numerous advantages, such as increased efficiency and consistent quality. These machines eliminate the need for manual tooling, reducing the margin for error and enabling rapid production of complex designs that would otherwise be time-consuming and difficult to achieve.

Choosing the Right Machine

Selecting the appropriate 3D foam CNC machine involves considering the specific requirements of the task at hand. Factors such as the intricacy of the designs, the volume of production, and the physical properties of the foam material all play a crucial role in determining the most suitable machine for a given project.