Popular in your industry

Top categories

About 300mm heatsink

Understanding Heatsinks for 300mm Applications

A 300mm application heatsink is a passive heat dissipation device engineered to cool electronic components and circuits. Crafted from highly conductive materials like aluminum or copper, these heatsinks efficiently channel heat away from the devices to which they are affixed. Their design varies in shape and size to meet the diverse requirements of different electronic systems.

Heatsinks play a vital role in averting component overheating, which can compromise functionality and reduce lifespan. With the advent of more potent and compact electronics, effective heat management is crucial to maintain peak performance. Heatsinks operate on the principle of thermal transfer, absorbing heat from the device and dispersing it into the ambient environment, thereby sustaining a temperature lower than the device's operational heat.

For entities and technicians engaged in electronic equipment maintenance, repair, or assembly, heatsinks are essential. Their use extends beyond high-end computers and gaming systems to industrial machines, automotive technology, and certain domestic appliances. Devices that handle high power or intensive processing are prime candidates for heatsink integration.

Varieties of Heatsinks for 300mm Applications

Heatsinks for 300mm applications come in several forms, each selected based on the heat management needs of the application, the type of heat-generating component, and the design limitations of the system.

-

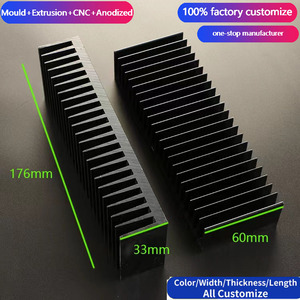

Extruded Aluminum Heatsink: A prevalent choice for cooling electronics, this heatsink is produced by extruding heated aluminum through a die, resulting in a finned profile that augments the surface area for heat dispersion and offers cost efficiency.

-

Cold Forged Heatsink: These heatsinks boast a denser composition and often surpass extruded types in efficiency. They are shaped at ambient temperatures, which refines the metal's grain structure for superior thermal conduction, making them suitable for more demanding cooling needs.

-

Skived Heatsink: Skived heatsinks, characterized by fewer, larger fins, are optimal when space constraints are minimal and a robust cooling solution is necessary for rigorous applications.

-

Heatpipe Heatsink: Combining heat pipes with aluminum fins, these heatsinks offer effective thermal transfer. The sealed heat pipes prevent air ingress or egress, ideal for precision cooling in delicate electronics.

-

Liquid Cooled Heatsink: For scenarios demanding superior performance, liquid-cooled heatsinks utilize coolants like water to achieve highly efficient cooling, especially where air cooling is inadequate or spatial limitations exist.

Selecting a Heatsink for 300mm Applications

Choosing a heatsink for a 300mm application requires careful consideration of several factors that correspond to the thermal demands of your device or system:

-

Thermal Conductivity: Materials vary in thermal conductivity; copper is often favored for its superior efficiency but may be impractical for certain applications due to its weight and cost compared to aluminum.

-

Size and Weight Constraints: The heatsink must fit within the designated space and be light enough to avoid exerting excessive stress on the mounting structure.

-

Fin Area and Airflow: A larger fin area enhances heat dissipation but necessitates sufficient airflow, which should be factored into the spatial arrangement around the heatsink.

-

Thermal Resistance: A lower thermal resistance indicates better heat dispersion, though this may entail a higher cost. Balancing thermal resistance with the device's heat dissipation needs is essential.

-

Materials: The operating environment of the application may dictate the choice of materials, especially in conditions with limited airflow or space, where efficient heat management is paramount.

By weighing these considerations against the available heatsink types, including active versus passive cooling options, firms can make informed decisions when selecting a supplier on Alibaba.com for their specific requirements.

About Heatsinks for 300mm Applications on Alibaba.com

Alibaba.com is an international marketplace that connects buyers with a plethora of suppliers offering a wide array of heatsinks for diverse industrial uses. For companies in search of effective thermal management solutions for their operations or for resale, Alibaba.com grants access to a global pool of suppliers vetted for quality and dependability, ensuring that businesses can source products that adhere to their performance and operational standards.

The platform's intuitive interface allows buyers to effortlessly sift through various options, comparing attributes like material composition and size compatibility, along with additional offerings such as bespoke logo imprinting. Alibaba.com's Trade Assurance service bolsters buyer confidence by protecting payments until delivery confirmation, underscoring the platform's commitment to secure transactions and its status as a vital resource for quality heatsink procurement.

Alibaba.com serves businesses of all sizes, from small workshops to expansive manufacturing facilities, providing products that match their operational needs and budgetary constraints. With Alibaba.com's extensive supplier network and robust support services, companies can optimize their sourcing process and acquire the necessary components for their industry-specific demands with efficiency.

Common FAQs for Heatsink for 300mm Application

What materials are commonly used for 300mm application heatsinks?

Heatsinks for 300mm applications are typically fashioned from materials like copper, aluminum, or a copper-aluminum alloy, known for their high thermal conductivity and effective heat transfer from the source to the heatsink.

How should I determine the appropriate heatsink size for my application?

The required heatsink size is contingent on the heat dissipation needs and the spatial constraints of your system. Considerations should include the heatsink's surface area as well as the airflow and spacing requisites.

Are heatsinks suitable for both passive and active cooling methods?

Indeed, heatsinks are adaptable to both passive and active cooling strategies. Passive heatsinks depend on natural convection or a heat source, whereas active heatsinks incorporate a fan or pump to enhance heat transfer.

Do heatsinks vary according to different applications?

Certainly, there are specialized heatsinks designed for particular applications. For example, pin-fin heatsinks excel in LED lighting cooling, while extruded heatsinks are better suited for high-power industrial machinery.

What are the benefits of custom heatsinks for 300mm applications?

Custom heatsinks offer the advantage of a thermal solution precisely tailored to your application's specific needs, ensuring optimal fit and performance. They can also accommodate unique shapes or sizes not covered by standard heatsinks.

How does thermal paste improve heatsink performance?

Thermal paste eliminates microscopic air pockets between the heatsink and the chip, enhancing heat conduction. It also stabilizes temperature by providing a direct thermal path from the heat source to the heatsink base.

What is the significance of a fin in heatsinks, particularly for 300mm applications?

A fin is a protrusion on the base material that expands the surface area for heat transfer. The design of the fin is critical as it facilitates greater airflow over the base, aiding in heat removal.

Is it feasible to use a heatsink designed for a different application in a 300mm setup?

Heatsinks should be specifically designed for their intended application; using an unsuitable heatsink can lead to inadequate fit, diminished thermal efficiency, and potential system failures.

What considerations are important when selecting a heatsink supplier on Alibaba.com?

When choosing a heatsink supplier on Alibaba.com, evaluate their industry experience, product quality, customization capabilities, adherence to industry norms, and the quality of customer service offered.