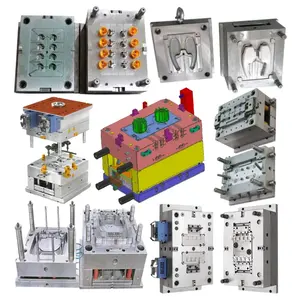

Introduction to 3 Liter HDPE Bottle Moulds

The 3 liter HDPE bottle mould is a specialized tool used for the production of high-density polyethylene bottles, commonly utilized in various industries for packaging purposes. This category encompasses a range of moulds designed to create durable and versatile containers with a capacity of 3 liters, catering to the needs of businesses requiring substantial volume packaging solutions.

Types and Applications

There are multiple types of HDPE bottle blow molds tailored to different production requirements. These moulds are employed in the manufacturing of containers for liquids such as beverages, chemicals, and cleaning agents. The adaptability of these moulds allows for their use in creating bottles for food-grade storage, industrial supplies, and even agricultural products, highlighting their diverse applications.

Features and Materials

A 3 liter bottle mould is characterized by its robust construction and precision design. The materials used in the creation of these moulds, such as steel and aluminum, are selected for their durability and resistance to wear. This ensures the longevity of the moulds and consistency in bottle production. Advanced design features include intricate cavities and cooling systems that aid in efficient manufacturing processes.

Advantages of Using HDPE Moulds

Utilizing a HDPE blow mould for 3-liter bottles offers several advantages. These moulds provide a cost-effective solution for mass production due to their long service life and low maintenance requirements. The flexibility in design allows for customization, enabling producers to create bottles that meet specific dimensional and aesthetic requirements without compromising on the container's integrity or functionality.

Optimizing Production with Standardization

Producers can enhance their operational efficiency by standardizing certain elements of their HDPE bottle moulds. By adopting uniform lift bars, connection sizes, and clamp slots, businesses can streamline their production lines, reduce setup times, and increase compatibility across different moulding machines. This strategic approach to standardization can significantly impact the scalability and flexibility of production operations.

Selecting the Right Mould for Your Needs

Choosing the appropriate 3 liter HDPE bottle mould requires careful consideration of the design, material, and specific production capabilities. It is crucial to collaborate with experienced mould manufacturers who can provide insights and support throughout the selection process, ensuring that the mould aligns with the desired output and quality standards. By leveraging the vast network of suppliers on Alibaba.com, businesses can find the right mould to meet their production needs and objectives.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4