Introduction to Carding Machines

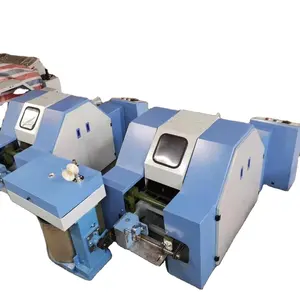

Exploring the industrial landscape, one encounters the india carding machine for sale, a pivotal component in the textile industry. Carding is the process that combs and entwines fibers to prepare them for the subsequent stages of textile production. The carding machine, therefore, stands as a cornerstone for transforming raw fibers into a uniform web, suitable for fabric manufacturing.

Types and Applications

The diversity of carding machines is evident in their design to accommodate various fiber types. Flat carding machines are tailored for short chemical fibers, ensuring precision and care in handling delicate materials. Conversely, roller card machines are adept at processing long chemical fibers, showcasing their versatility in the textile sector. The application of these machines extends across different materials, each requiring a unique approach to achieve the desired carded output.

Operational Features

Understanding the operational features of a carding machine manufacturer is crucial for optimal performance. Flat carding machines necessitate a consistent layer of cotton feed, achieved through sophisticated opening and scutching machines. Roller card machines, on the other hand, employ a weighing device to deliver equal quantities of fiber at set intervals, ensuring uniformity in the carding process. These operational nuances are essential for producing a consistent and high-quality carded product.

Considerations for Purchase

Selecting a textile carding machine involves several critical considerations. The size of the machine must align with the operational space, ensuring seamless integration into the production environment. Material type is another pivotal factor, as different machines are optimized for specific fibers. Additionally, the availability of spare parts is a practical concern, given the extensive operational hours of carding machines and the inevitable wear of components. Lastly, the warranty period offers a layer of assurance regarding the machine's reliability over time.

Advantages of Carding Machines

The advantages of utilizing a fiber carding machine are manifold. These machines enhance the uniformity and quality of the carded product, which is essential for high-grade textile production. The precision with which these machines operate allows for a significant improvement in the efficiency of the carding process, ultimately contributing to the overall productivity of the textile manufacturing operation.

Choosing the Right Machine on Alibaba.com

For those in the market for a carding machine for nonwoven, Alibaba.com presents a comprehensive collection of machines to suit varied needs and preferences. The platform facilitates an efficient selection process, allowing buyers to compare different models and features without the constraints of time or location. With a focus on connecting buyers with reputable suppliers, Alibaba.com streamlines the procurement of industrial machinery, including carding machines, to enhance textile production capabilities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4